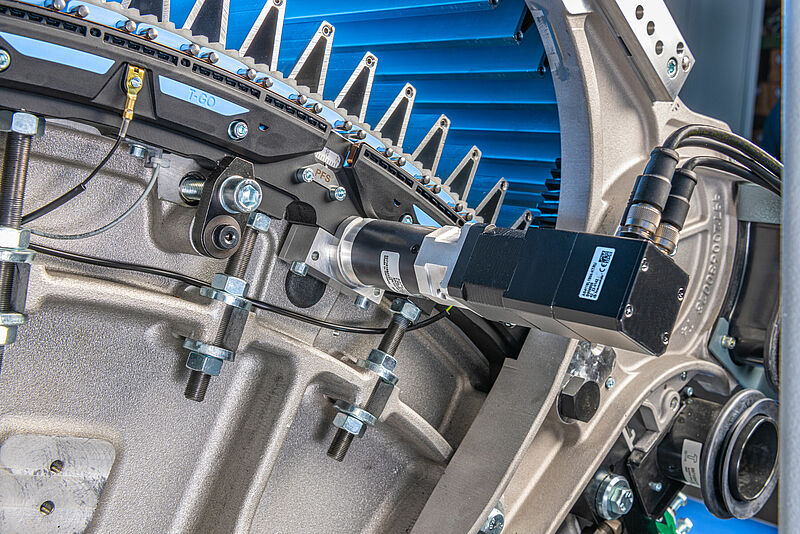

Operator-independent high performance with T-GO gap optimizer

- Always a constant and optimal carding gap

- Increase quality and productivity flexibly

- Achieve consistent results independent of operator and environment

.

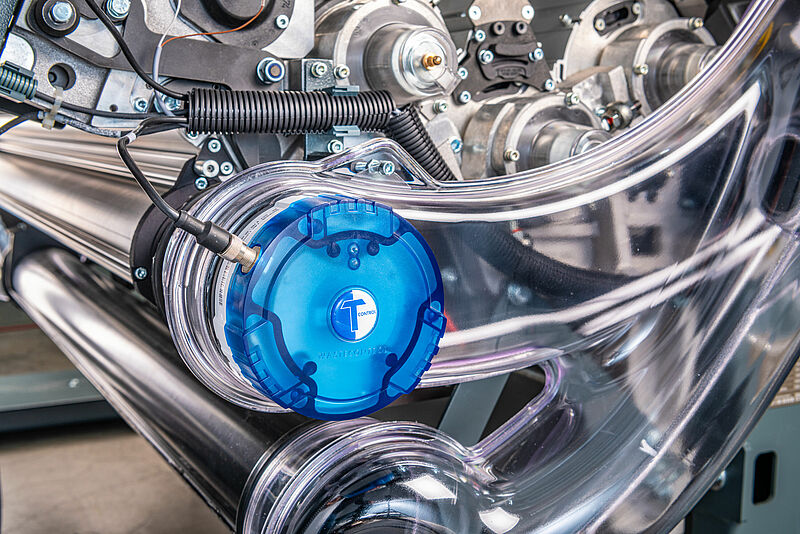

Up to 2 % raw material saving with WASTECONTROL and PMS 2

Our proven WASTECONTROL sensor, which permanently monitors the waste quality at the licker-in, is your insurance against unnecessary waste. The new mote knife system PMS 2 allows even more flexible settings for waste extraction.

Less energy consumption

The main reason for the energy efficiency of the TC 26i is the low suction pressure and the low air requirement. At the same time, the need for compressed air has been reduced to a minimum. The TC 26i enables you to achieve higher production rates, which decreases energy consumption per output (kg).

Low maintenance and easy handling

The user-friendly design with quick access from all sides makes it easy to carry out regular maintenance work. This accelerates maintenance and reduces machine downtime.

TC 26i and My Mill, our digital mill monitoring system

My Mill offers you a transparent view of your entire spinning mill.

Generate quick wins, cut costs, save time and optimize processes with little effort.

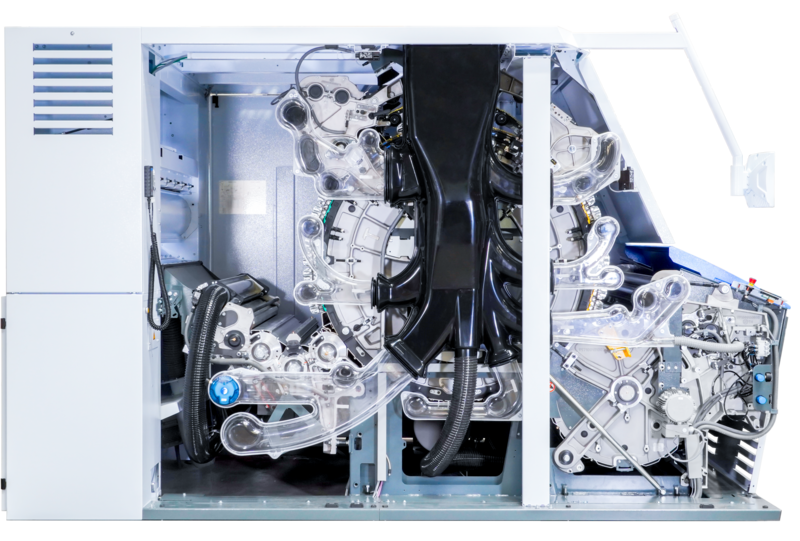

TC 26i: One card for all applications

The next-generation TC 26i carding machine is available in four versions that are designed for specific processing parameters:

- TC 26i: For cotton fibers

- TC 26Si: For man-made-fibers

- TC 26Ri: For recycled fibers

- TC 26Fi: For particularly fine yarns