Airjet Spinning

Leading edge for airjet yarns

Particularly in the spinning mill with its numerous machines, reduced process stages quickly multiply to great economic advantages.

The Truetzschler spinning preparation gives you the option to drastically shorten the preparation process on IDF 3 and autoleveller draw frame. But even when using the classic process with three passages you can increase productivity thanks to the efficient TWIN BUT INDEPENDENT concept.

The best process for your yarn

100 % viscose / 100 % polyester – shortened

Preparation has never been that short

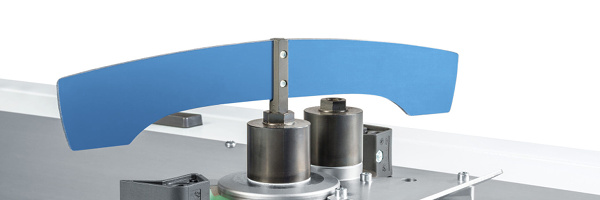

Process shortening with only one draw frame passage for airjet yarns is only possible thanks to the Integrated Draw Frame IDF 3. In combination with the intelligent card TC 30i you get the most economical airjet yarn this way. Ne 10 – Ne 40

100 % man-made fibers – 3 passages

Customised man-made fiber opening for perfect carding and drafting

The modular Truetzschler blowroom offers customised solutions for your requirements. Especially the stainless steel equipment in the blowroom and card allow a trouble-free production of man-made fibers.

100 % cotton – 3 passages

The perfect cotton installation from bale opening to combing and draw frame

The cotton is gently opened in precisely synchronised machines. The self-optimization functions of our machines and the focus on resource-conserving production make the difference in your raw material utilization and yarn quality, especially when processing cotton. The use of the economical JUMBO CAN is therefore particularly recommended here.

Tuft blending

The perfect blend

Our T-BLEND installation enables homogeneous and economical blending of fiber tufts at an exact blending ratio thanks to the weighing process. If you would like to blend combed cotton as tuft, the Comber TCO 21 XL offers the possibility of returning the material as tuft to the blowroom.

Draw frame blend

Flexible installations for your airjet yarn

Flexibility is the keyword for many of our customers. Thus, Truetzschler offers tailor-made installations for your end product with the modular blowroom concept. Those who also count on flexibility in the process stages will find the right solutions with the Truetzschler draw frames. Thanks to the TWIN BUT INDEPENDENT concept, even different materials or process stages can be run on one breaker draw frame.

Blow room | T-BLEND | Card TC 30i | Integrated draw frame IDF 3 | Draw frame TD 9T | Superlap TSL 12 | Comber TCO 21XL | Draw frame TD 10